CNC Fabrication: Save the Ponds Project

Project Scope

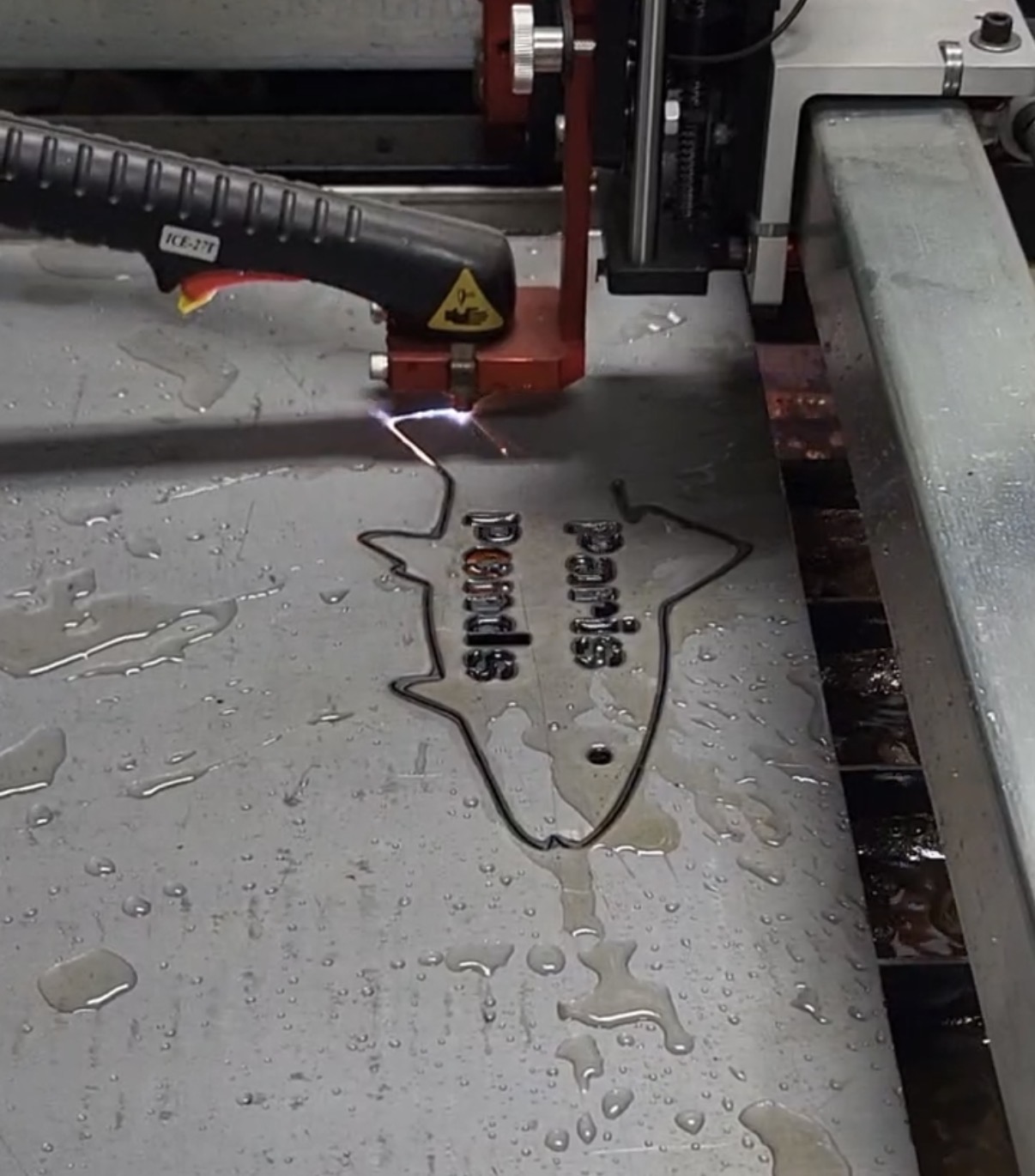

I was commissioned to design and fabricate custom metal “donor plaques” for the Save the Ponds project in Paris, Michigan. The initiative aims to restore the historic ponds at the Paris Park Fish Hatchery. This project required a scalable manufacturing process to produce unique, weather-resistant steel plaques for each donor level.

The Challenge

The project required producing a high volume of aesthetic metal parts that were durable enough for permanent outdoor installation in a Michigan winter.

- Customization: Each plaque needed to potentially bear a different donor name, requiring a parametric workflow in Fusion 360 to update text without breaking the geometry.

- Manufacturability: The design had to account for the “Kerf” (cut width) of the plasma torch to ensure legible text on smaller fish.

- Material Efficiency: Parts needed to be “nested” tightly on the steel sheet to minimize scrap cost for the non-profit fundraiser.

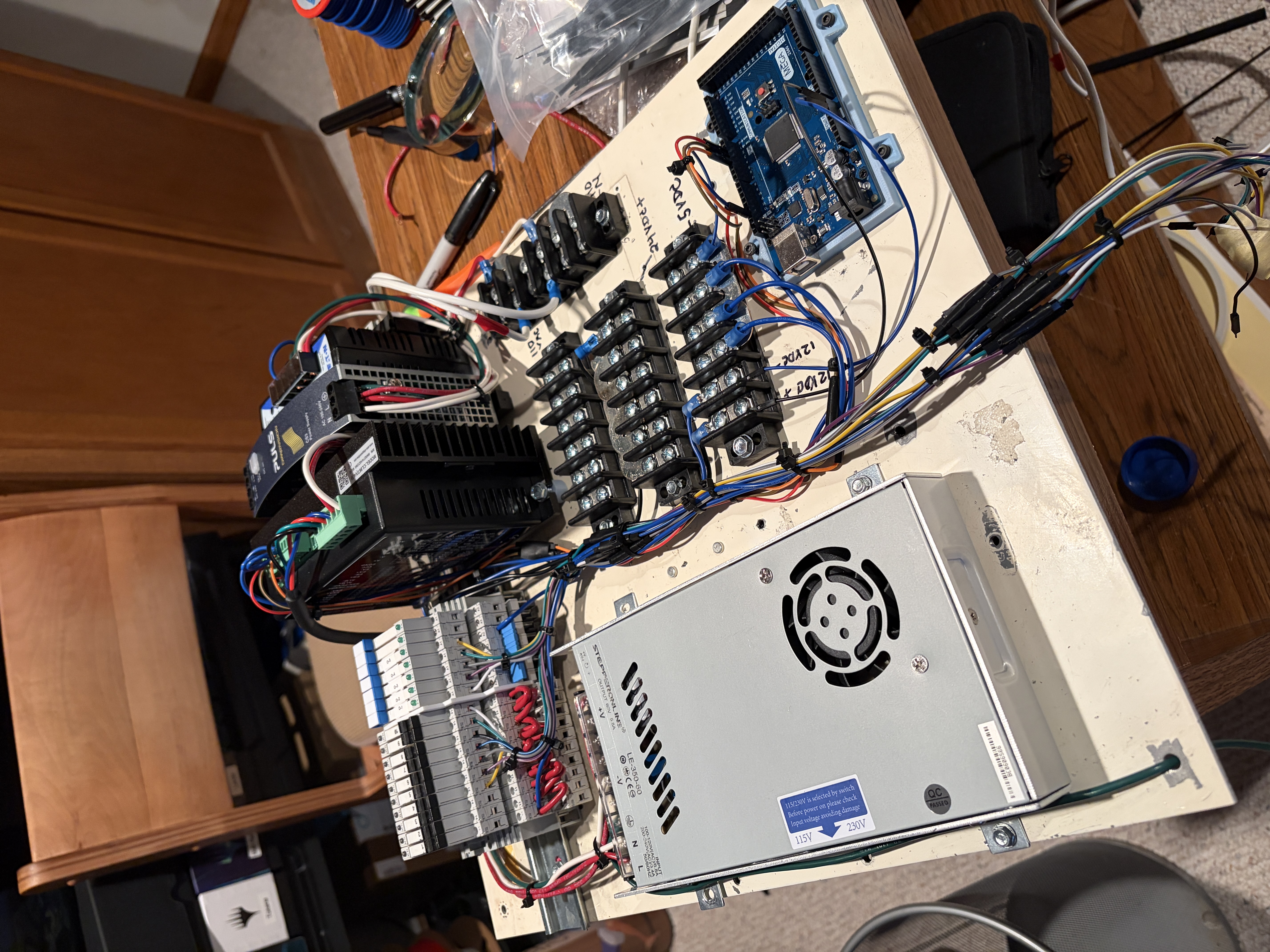

Technical Implementation

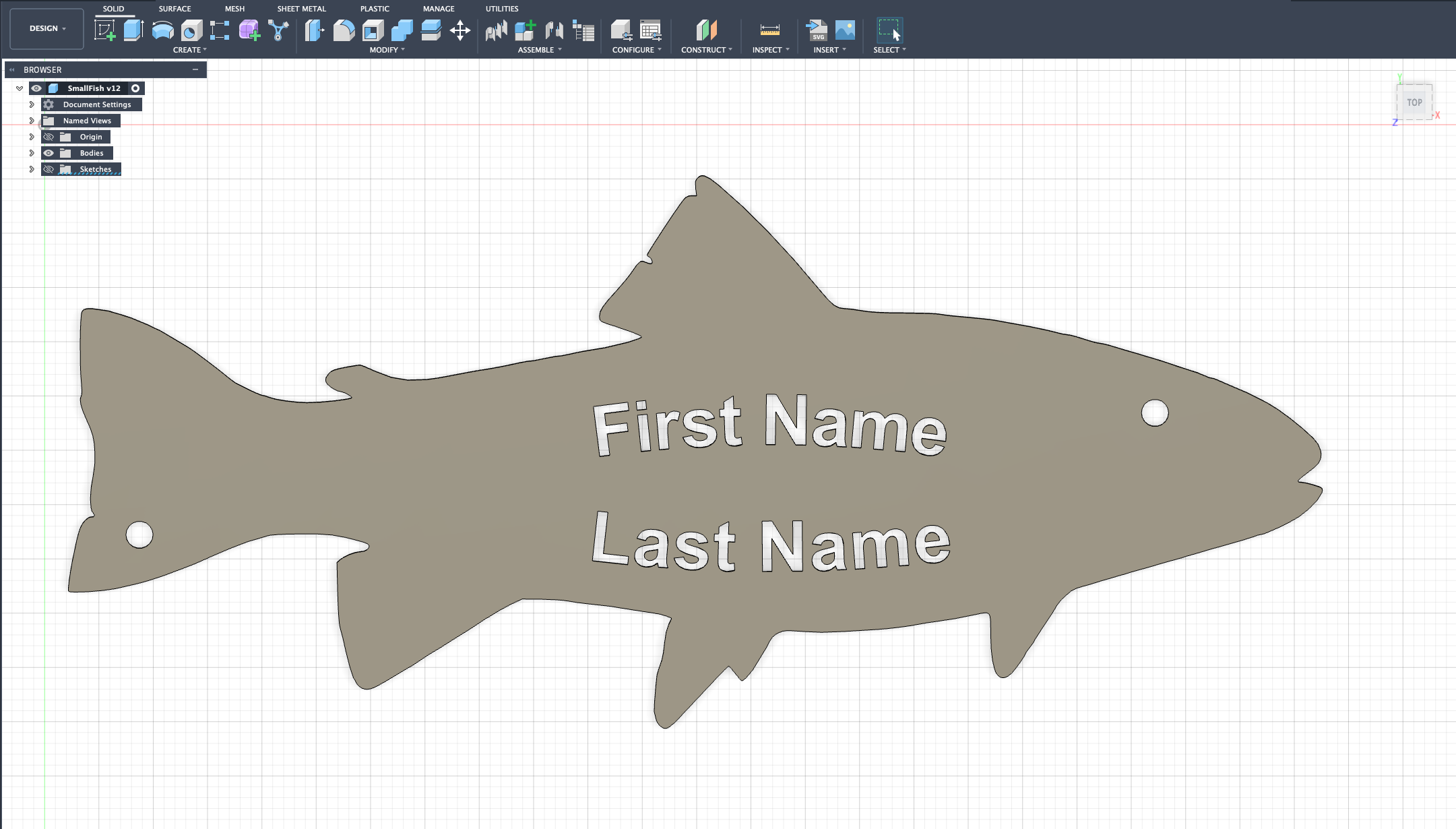

CAD Design & Stenciling (Fusion 360)

I utilized Autodesk Fusion 360 to design the parametric fish geometry. A critical engineering decision was the Typography Selection to ensure successful plasma cutting:

- Design for Manufacture (DFM): Standard fonts are unsuitable for CNC cutting because the centers of “closed loop” letters (like ‘O’, ‘A’, and ‘D’) fall out when cut. I selected a specialized Stencil Typeface with pre-engineered bridges to retain internal geometry.

- Kerf Consideration: I chose a bold, heavy-weight font variant to ensure the bridge width exceeded the plasma torch’s kerf (cut width). This prevented the connecting material from melting away during the cut, ensuring structural integrity without requiring manual vector repair.

CAM & G-Code Generation

- Nesting Strategy: I optimized the layout of parts on the 4x8 steel sheet to maximize yield.

- Toolpath Strategy: Configured lead-ins and lead-outs (where the torch starts cutting) to occur on the scrap skeleton, ensuring the edge quality of the finished fish remained smooth.

- Cut Parameters: Tuned the cutting amperage and feed rate (IPM) specifically for the steel gauge to minimize “dross” (slag) and reduce post-processing time.

Community Impact

This project directly supports the preservation of a local historical landmark. By providing in-house fabrication, I significantly reduced the cost compared to outsourcing to a commercial sign shop, maximizing the funds going directly to the hatchery restoration.

Gallery

From digital vector design to physical steel installation.